Plumbing and Mechanical Piping

The MAPA “Master Base” is designed for use as a cost-effective, heavy-duty, non-penetrating, free standing pipe support stand for all applications within the recommended weight limit.

This base is typically used for supply and return piping, duct systems, roof mounted equipment or any application where heavy-duty support is needed. The strut flange may be factory modified to meet design criteria for roofs with increased slope.

The welded support flange accepts 1-5/8" square strut. The bases have rolled edges and notched corners to prevent incidental damage to roof surface and prevent standing water. Includes hardware for strut/tubing attachment to the base. An optional 1/2" thick rubber walk pad may be adhered to the base providing additional protection for the support structure

- All Stainless-Steel Hardware.

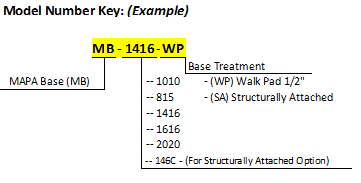

- Available in multiple sizes for various load ratings, most commonly as MB-815 , MB-1416 and MB-2020, refer to "Model Numbers" for additional details.

- Available with ½” HD Walk Pad.

- Steel hardware.

- Free Standing or Structurally Attached.

- Designed and manufactured in compliance with the International Fuel Gas Code, MSS SP-58-2002, MSS SP-69-2002 and MSS SP-127-2001where applicable for structural support systems.

Features:

Equipment Support Systems

Equipment Supports: MAPA utilizes our Master Base design to manufacture various equipment platforms, walkways and crossover systems. It is available with either a corner or side bracket. The size and weight of the unit will determine the necessary base size.

MS-1-C-P: This corner-mounted base provides an economical method of supporting roof mounted equipment. The non-adjustable base assembly is manufactured from a fiberglass reinforced 6/6 Nylon with a rubberized protective coated metal corner assembly which is then covered with a neoprene pad. The optional neoprene pad adhered to the base provides additional protection for the roof.

Walkways, Crossovers and Platform Support Systems

- Free Standing or Structurally Attached base design Platform - HDG Bar Grating sized according to Equipment type, Dimensional and Load Data

- 1 5/8" weather treated strut or telescoping strut for columns

- Maximum weight load in accordance with base model.

- see additional information in the Master Base section

- Recommended 1/2" thick rubber walk pad

MCO Equipment Platform

- Free Standing or Structurally Attached base design

- 12" Galvanized Step Planking for surface

- 1 5/8" weather treated strut or telescoping strut for columns

- SS Master Base MB-815, bases with larger footprints can be used

- (1) Stair Assembly and (1) sided Hand Rail so that Equipment can be accessed from Platform.

- Recommended 1/2" thick rubber walk pad

MESP Equipment Service Platform

- Free Standing or Structurally Attached base design

- 12" Galvanized Step Planking for surface

- 1 5/8" weather treated strut or telescoping strut for columns

- SS Master Base MB-815, bases with larger footprints can be used

- (2) Stair Assemblies and (2) sided Hand Rails

- Recommended 1/2" thick rubber walk pad

MCO Cross Over

- Free Standing or Structurally Attached base design

- 12" Galvanized Step Planking for surface

- 1 5/8" weather treated strut or telescoping strut for columns

- SS Master Base MB-815, bases with larger footprints can be used

- Recommended 1/2" thick rubber walk pad

MWW Walk Way

Related Accessories

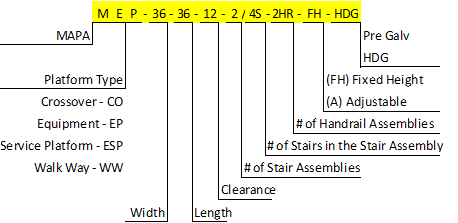

- Material: 100% Recycled Black Rubber Surface: Flat smooth

- Back Side: Wire mesh texture, anti-skid sur- face.

- Weight 3 lbs. square foot. Sizes: Varies by support.

Walk Pads

- 2-Hole, Heavy-Duty Stainless-Steel Pipe Straps.

- Pre-formed to secure tubing to roller supports with a loose fit allowing for expansion and contraction of the pipe.

- Pipe Straps are set over the pipe then secured with provided hardware.

Pipe Strap

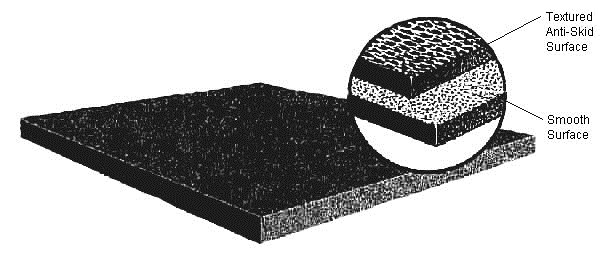

Roller Assemblies

- Available as adjustable or fixed height assemblies

- Stainless steel axle and a UV protected rubber roller

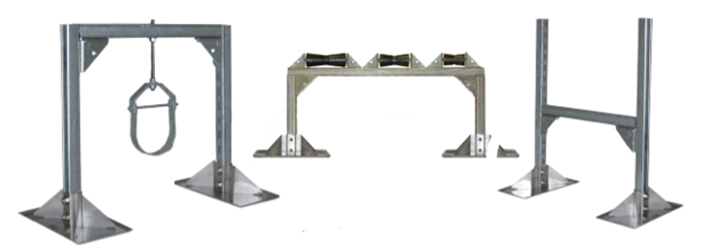

Model Numbers

- Additional Notes:

Weight limits are established by the contact area of the support to roof surface with a maximum load per square inch of 5 lbs. SA (Structurally Attached Supports) where structural blocking is utilized; load is transferred directly to the structure; thereby increasing the allowable load, as approved by the structural engineer, any increased loading should not exceed 500 lbs. Where installation height exceeds 12” refer to MAPA Products “Recommended Installation Guidelines”

Downloads

- Installation and Maintenance

- Trapeze Install

- Engineering and Submittal

- Submittal MB-1416

- Submittal MB-2020

- Submittal MB-815

- Submittal MX146C-SA